The USS Vision Surface Scan utilizes state-of-the-art deep learning technology, which harnesses the power of neural networks to emulate human intelligence. This innovative approach enables the system to accurately distinguish anomalies, parts, and characters while accommodating natural fluctuations within intricate patterns.

Unlike conventional machine vision methodologies, which struggle to detect deviations and variations among visually similar parts, deep learning algorithms offer a notable advantage. The advanced software tools of USS Vision Surface Scan, based on deep learning, provide superior solutions for intricate tasks, including part location, inspection, classification, and character recognition, surpassing both human and traditional machine vision techniques in accuracy and efficiency.

APPLICATION EXAMPLES

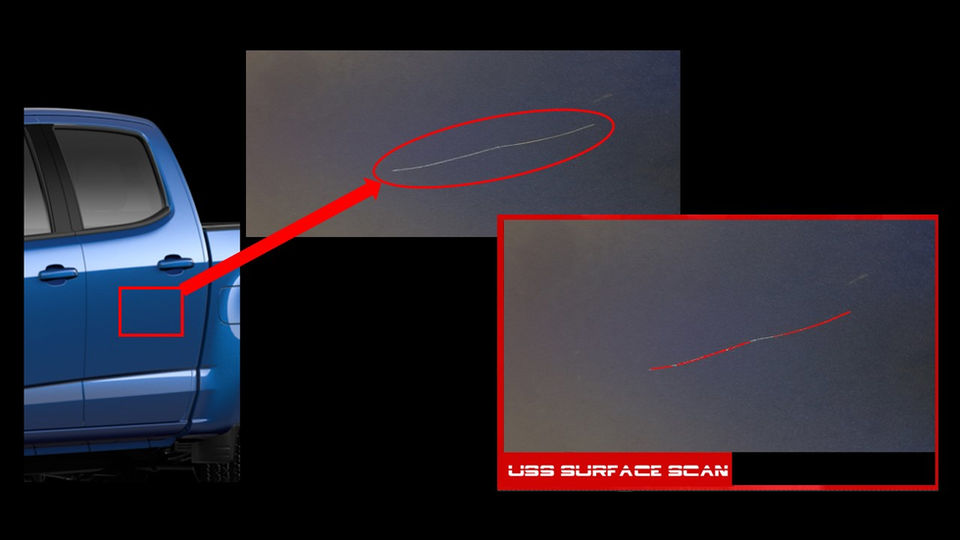

Inspect for scratches

Check fabric and leather quality

VIN Inspection

Surface Finish

Categorize different part types

Inspect for porosity

SPLIT DETECTION

USS Vision has once again achieved a technological milestone with our latest innovation.

In the manufacturing of stamped metal parts, natural splits commonly occur in corners and deep draws, posing a challenge for human identification and preventing them from being assembled into finished products. To overcome this issue, traditional machine vision systems have been explored, but have fallen short due to their unreliable split detection capabilities.

However, recent advancements in machine learning and artificial intelligence have enabled us to develop a highly effective solution. By leveraging our expertise in this domain, we have created a state-of-the-art machine-learning model that can accurately detect splits as small as 3mm in length. Our refined split detection kit can be easily installed in or near a variety of stamping presses, with the accompanying machine-learning model template allowing for swift commissioning.

Moreover, our machine learning software has been designed to continuously refine itself over time, further improving the accuracy of split detection. With our system meeting machine vision Gage Repeatability and Reproducibility standards, it offers a reliable and cost-effective solution to improve product quality while reducing labor costs for our valued customers.

Get in touch with us today for a demo of our cutting-edge split detection technology.

VIN DETECTION

The limitations of traditional machine vision techniques have made it challenging to accurately detect vehicle identification numbers (VINs) that are difficult to read. The material on which a VIN is marked undergoes changes over time, and markers can degrade, resulting in the need for constant software programming modifications. End users are required to monitor the systems closely to prevent issues such as no-reads or misreads, which can potentially compromise traceability standards.

However, machine learning technology has revolutionized VIN detection by enabling reliable identification of VINs marked on a broad range of materials such as metals and plastics, using various laser and pin-stamp markers. Our cutting-edge software utilizes robust algorithms that accurately distinguish characters, even on marking surfaces that change over time, such as batch-to-batch variations.

Our software models are continuously updated and improved, even while you sleep, ensuring the highest levels of performance and accuracy. If you are not satisfied with your current reader, do not hesitate to contact us for an upgrade. If you are looking for a new, reliable VIN reading system, we are your go-to solution.

Feel free to contact us to set up a demo and experience the power of our technology firsthand.