The USS Vision Exact Scan™ is a cutting-edge, patented machine vision inspection system designed to deliver high-performance scanning capabilities for multiple features at super-high resolutions (12,000 x 9,000 pixels). The system comprises a unique vision sensor, as well as specially-designed lighting systems that have been rigorously tested for suitability across a range of manufacturing applications. The system boasts a small footprint, making it an ideal solution for manufacturers who require a high level of inspection accuracy in compact spaces.

The Exact Scan™ machine vision software is powered by robust software tools, featuring a simple, user-friendly front-end display that is easily navigable for plant engineers. The software runs on the Windows operating system, and is designed for ease of use and quick learning.

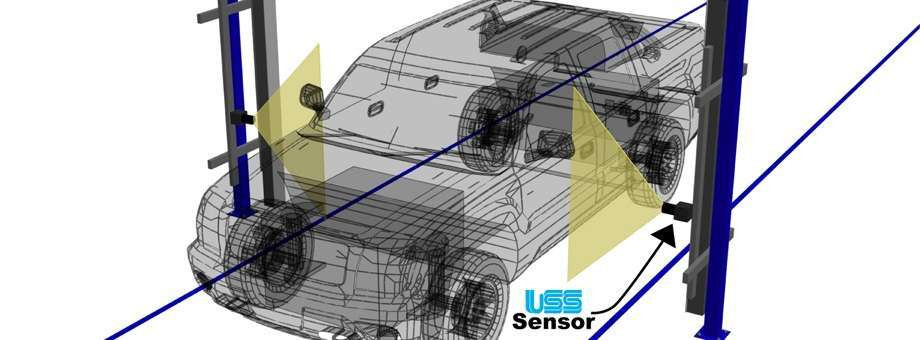

Unlike traditional inspection systems that rely on multiple sensors to inspect different features, the USS Vision Exact Scan™ replaces them with a single sensor per side, significantly reducing overall cost and maintenance requirements. The sensors are engineered to deliver exceptionally precise measurements, and inspect multiple features at once.

The system generates an abundance of data, with pass/fail data and part identity stored in the PC. The system captures and stores images automatically, along with the part identity, providing plant engineers with real-time access to data on the cloud via the USS Vision Image-Drive™. The system requires only a single 110 power source, and communicates seamlessly with manufacturing plants' communication networks via Ethernet or serial connections. With a single sensor, the USS Vision Exact Scan™ delivers unparalleled inspection capabilities for multiple features at super-high resolutions, making it the ideal solution for manufacturers seeking to optimize their inspection processes.